VACUUM FURNACES

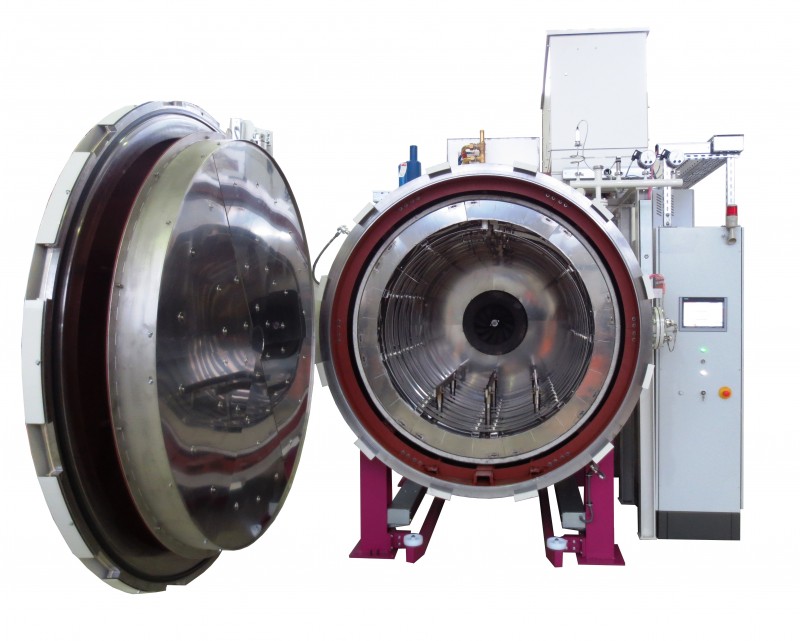

Vacuum tempering furnace with direct heating type VAD

After hardening in a vacuum furnace the most parts are metallic bright and clean. Therefore in such cases for the tempering process a vacuum tempering furnace with direct heating type VAD of the latest generation is recommended in order to prevent oxidation of the component surface reliably.

In addition vacuum tempering furnaces type VAD can be used for a wide range of heat treatment processes under vacuum up to temperatures of 850 °C and sub-zero treatments. Especially in high-alloyed tool steels after the hardening process a remarkably amount of retained austenite will occur. By a sub-zero treatment this amount can be reduced to a minimum.

Advantages:

- Suitable for a variety of heat treatment processes

- Consistent treatment results, even under the most difficult conditions

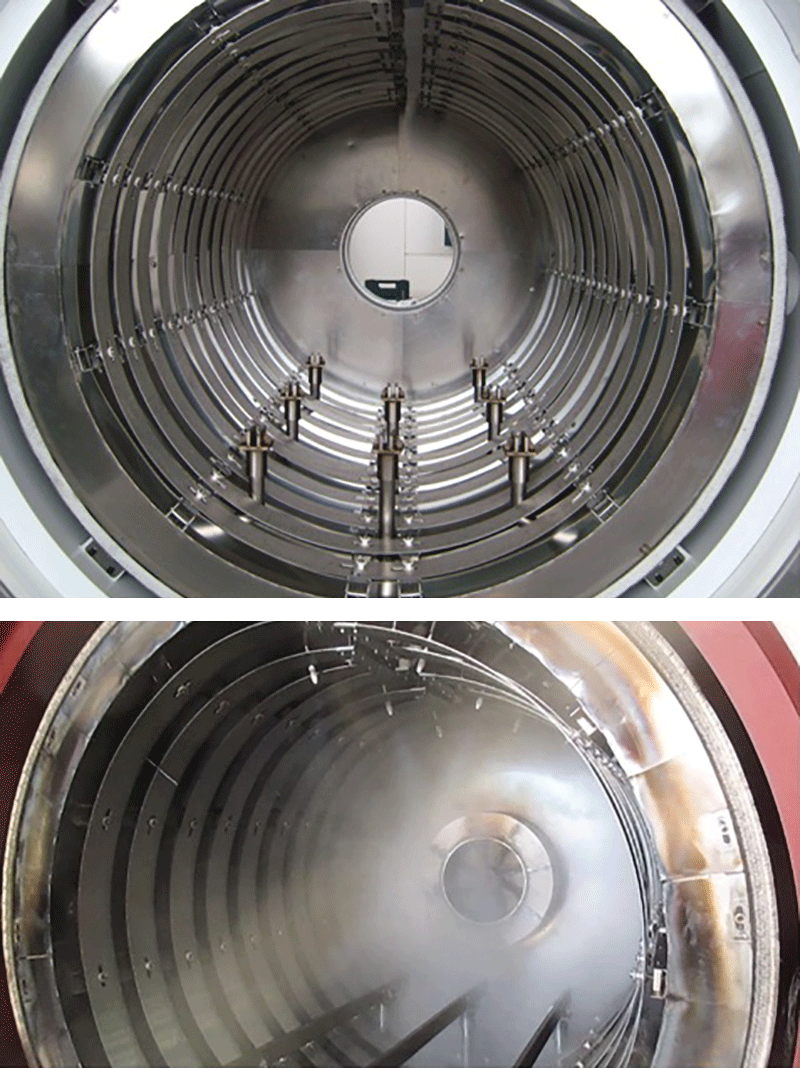

- Unbeatable uniformity during heating up and cooling due to belt heating elements (stainless steel)

- Heating up- and quenching characteristics according to your requirements

- Meet all current aviation standards (AMS 2750 E, NADCAP, etc.)

- Easy and reliably operation via touch screen

- Separate control system software “hestia”

- Several vacuum options regarding vacuum pumps

Special features:

- Hot box made out of stainless steel

- Integrated rapid cooling system

- Integrated intensive cooling system

- Temperature range from -180°C up to 800°C

- Low energy consumption

- Bright parts after treatment

- Also available with nitriding option

Standard sizes:

Type useable dimensions

(WxHxL in mm)

VAD 446 400 x 400 x 600

VAD 669 600 x 600 x 900

VAD 9812 900 x 800 x 1200

Other sizes and technical details are available on request.