Control and monitoring

Furnace control

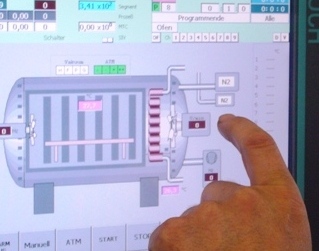

Our system controls offer the best combination of technology, system control and software on the market. Software is the heartbeat of our systems and combines reliability and failure safety of the programmable logic controllers with maximum flexibility and user-friendliness via the graphical user interface. Via state-of-the-art touch panels, the user is informed at any time about the current furnace status and all process-relevant data. SYSTHERMS software plans, manages, monitors and documents. And exactly as the customer requires. Around the clock. Fail-safe. We can guarantee this for the simple reason that both the touch panel and the control system are programmed 100% in-house at SYSTHERMS. Hardware and software in perfect dialogue – the decisive benefit for more practicability and functionality.

With SYSTHERMS furnaces, the user always has a graphical user interface available with the touch panel. This touch-sensitive screen offers a variety of display and input options and informs the user at any time in a clear and concise manner about the furnace status and all relevant process data. In addition, the user is given the opportunity to create, manage and start heat treatment programs and to define a number of different parameters. Additional systems such as gas supply and water recooling systems can also be operated via the touch panel.

- Furnace picture

- Creating programs

- Running programs

- Setting limit values

- Setting controller parameters

- Setting of correction values after TUS and SAT measurement

- Service mode

- Plausibility check for programs

- Transfer of the programs to the PLC

- Limit of the electronic power consumption of the furnace (power management))

- Control and parameterisation of accessory systems (cooling water recooling, gas supply, …)

On board: the touch panel

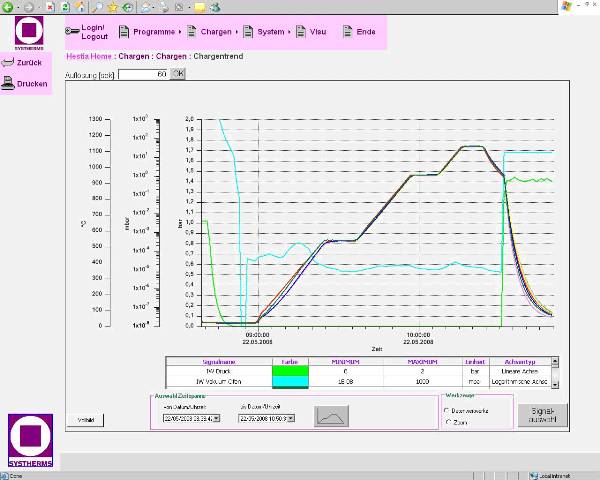

Guide system hestia

In order to be able to handle extensive additional tasks in connection with heat treatment, the touch panel is supplemented by the computer-aided software of our control system „hestia“. The system not only saves heat treatment data, it is also able to manage batches and print out protocols. The convenient trend display with practical zoom function allows individual values to be displayed from the overview display and heating and cooling rates between two points to be calculated automatically. In plants with several furnaces, these can be easily integrated into the system. An interface to order management systems frequently used in hardening shops is already integrated in hestia.

The convenient trend display with the universal zoom function allows individual values of the overview to be displayed and heat-up and cooling rates between two points to be calculated automatically.

In companies with more than one furnace, these can also be integrated into the system. An interface to order management systems frequently used in hardening shops is already integrated into hestia.

- Storage of program data

- Intelligent alarm assistance

- Alarm statistics according to duration or frequency

- Management of furnace batches

- Batch photo management

- Printout of batch records

- Integration of other furnaces

- Possibility of interfaces to ERP systems such as SAP and Oracle

- Customised reporting

Contact

SYSTHERMS GmbH

Gutenbergstrasse 3

D-97297 Waldbüttelbrunn

Phone: +49 (0) 931 35 94 30

Fax: +49 (0) 931 35 94 320

E-mail: Contactform

Overview

Quality & Reliability with SYSTHERMS