VACUUM FURNACES

Vacuum heat treatment furnace type VWC

Vacuum heat treatment furnaces type VWC can be used for a variety of heat treatment processes such as for example low carburizing, hardening, tempering, annealing or brazing. In this furnace with cylindrical heating chamber the usable space consists of a graphite cylinder in which are located curved graphite heating elements. Compared to conventional polygon segments significantly fewer fasteners are needed,which represent thermal bridges. Thus up to 20% less energy is required for heating.

The cylindrical chamber design is advantageous for the charging of components whose dimensions are partially outside the specified work space. The quenching gas is directed through nozzles at the cylinder wall radially onthe batch and then guided axially rearwardly to acopper heat exchanger.

Advantages:

-

suitable for a variety of heat treatment processes

-

uniform treatment results, even under most difficult conditions

-

highest temperature uniformity during heating and quenching by using band heating elements (graphite oder molybdenum)

-

heating and quenching characteristics according to your requirements

- complies with all current aviation standards (AMS 2750 E, NADCAP, etc.)

-

simple and secure control via touch screen

- proper control system „hestia“

-

different high vacuum options: oil diffusion pumps, turbo molecular pumps, cryo pumps

Special functions:

- heating chamber made of one graphite cylinder, fixed with no pins which means less thermal bridges

- metallic design of the heating chamber is possible

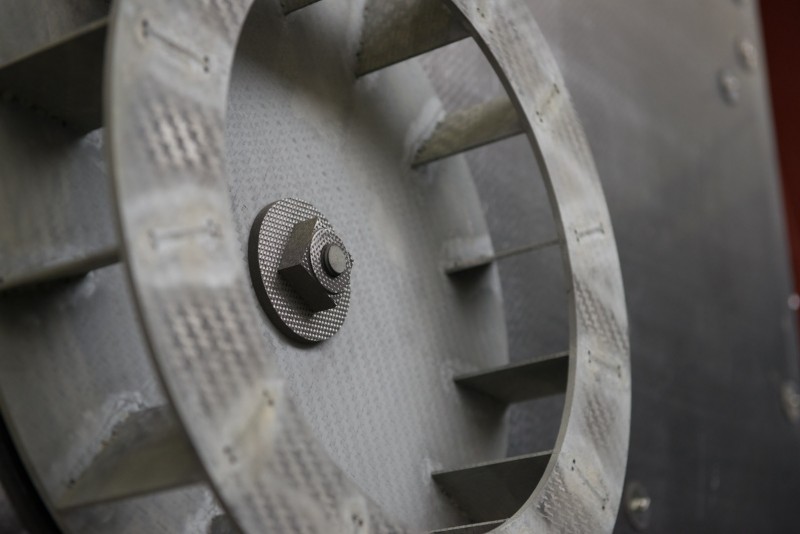

- convective blower manufactured of one CC fan wheel – more efficient and higher uniformity during convective heating (see photo on the right)

- quenching pressure up to 20 bar is possible

- highest quenching rate by special positioning of nozzles for the quenching gas

- full speed of the gas blower under vacuum is possible

Standard sizes:

Type usable dimensions

(WxHxL in mm)

VWC 446 400 x 400 x 600

VWC 669 600 x 600 x 900

VWC 9812 900 x 800 x 1200

Other sizes and technical details are available on request.